Description

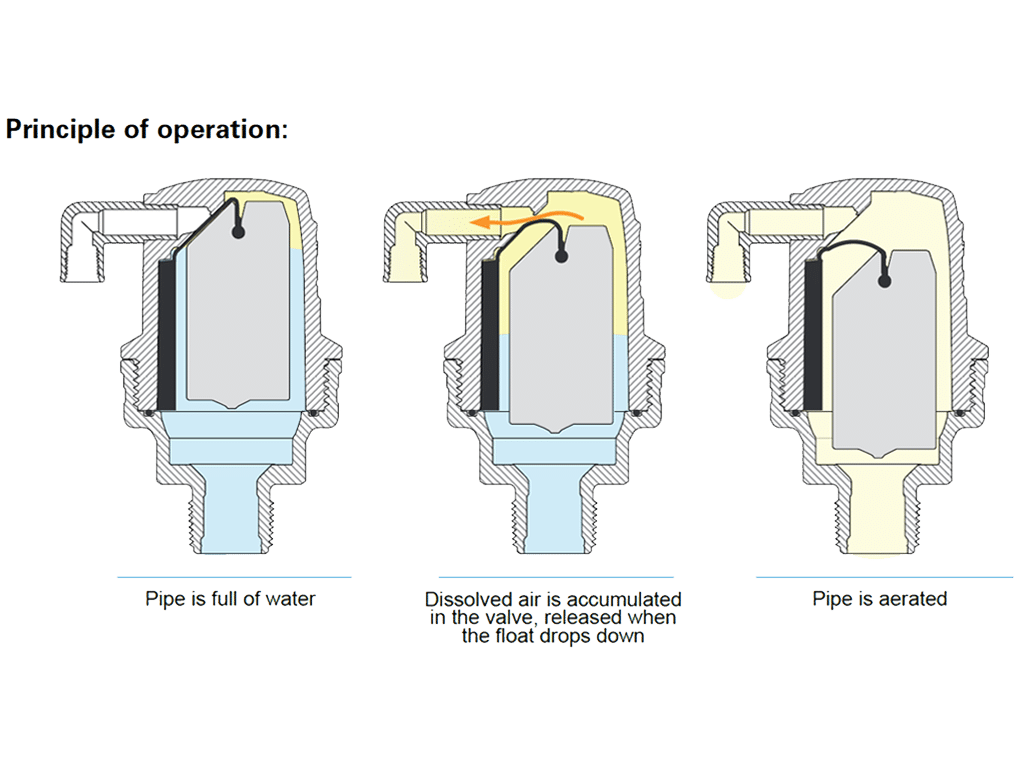

The valve is designed for an efficient release of entrapped air from the pipeline, while the network is at normal working pressure.

Due to the relatively large orifice, compare to other Automatic valves in the market, it can also release the air through initial filling of a small-diameter pipe, or admit air into it while it is drained.

Properties

An Automatic air valve, that enables the release of dissolved air that accumulate in the pipeline. The valve will release the air at normal operation pressures of the pipeline.

The Float is made of naturally-buoyant material (specific weight lower than 1). The float activates a sealing stripe, that closes the outlet when the water will fill the valve body.

On accumulation of air in the valve, loss of buoyancy causes the float to drop and to pull the strip, thus opening of the air outlet. The Hydraulic sealing of the orifice will provides a drip tight closure at a pressure of 2mwc (3psi).

Operation

Releasing entrained air from the pipeline. Small quantities of diluted air accumulate in high peaks of the pipeline and in the peak of the valve.

The pressurized air expels the water. The descending water level moves the main float with it. At a certain position the main float pulls down the small seal, that partially opens the nozzle.

The pressurized air can escape, the water level rises and the nozzle re- closes.